Shape Memory Alloy Products

Shape Memory Alloy Products

Memory Alloy

Shape memory alloys (SMAs) are a unique class of smart alloys that have the ability to ‘remember’ their original shapes. SMAs can be deformed when cold (Martensite) and return to their memorized shapes when heated (Austenite) even after strong deformation, this is the so-called Shape Memory Effect (SME). The other main property of SMAs is the super-elastic effect; superelasticity allows the materials to be recovered from large mechanical stresses without plastic deformation. Beside these two major properties, compared to the conventional alloys, SMAs also show excellent traits such as high strength, light weight, biocompatibility, fatigue resistance and wear resistance.

Shape Memory Alloy Field

The most commonly used shape memory metal is Nitinol (NiTi), which comprises a roughly equal parts of Nickel and Titanium, in addition to excellent shape memory effect and superelasticity, it also has excellent corrosion resistance, high damping performance and biocompatibility. They are broadly used in the fields of medical, military, aerospace, industrial, consumer electronics, home appliances, et cetera.

Shape Memory Alloy Application

TRIAD pioneered and matured the R&D and applications of SMAs in China. With more than 20 years of experience in producing and applying NiTi shape memory alloys, we have accumulated mature production technologies and have achieved long-term product applications in eyeglass frames, underwear accessories, medical implants, temperature control sanitary wares and many other fields.

Shape Memory Alloy Products

As the pioneer of research and development of shape memory alloys in China, TRIAD explored the application of SMAs in daily life, such as the market for eyeglasses and clothing.

Nickel Titanium Shape Memory Alloy is mainly used in the middle beam and temple parts of eyeglasses, with the advantages of light weight, biocompatibility, wear resistance, and compression resistance. The super elasticity ensures the frames to be very durable and strong that they can even be bent back and forth. After more than 20 years of unremitting efforts, SMA has become the preferred material for high-end eyeglasses.

The application of SMAs to the underwire is also a significant global market for SMA; women’s brassieres have both aesthetic as well as structural requirements; NiTi underwires offer improved comfort due to the much lower elastic modulus than the conventional steel wires, and the material offers greater resistance to permanent deformation due to the frequent washing and drying.

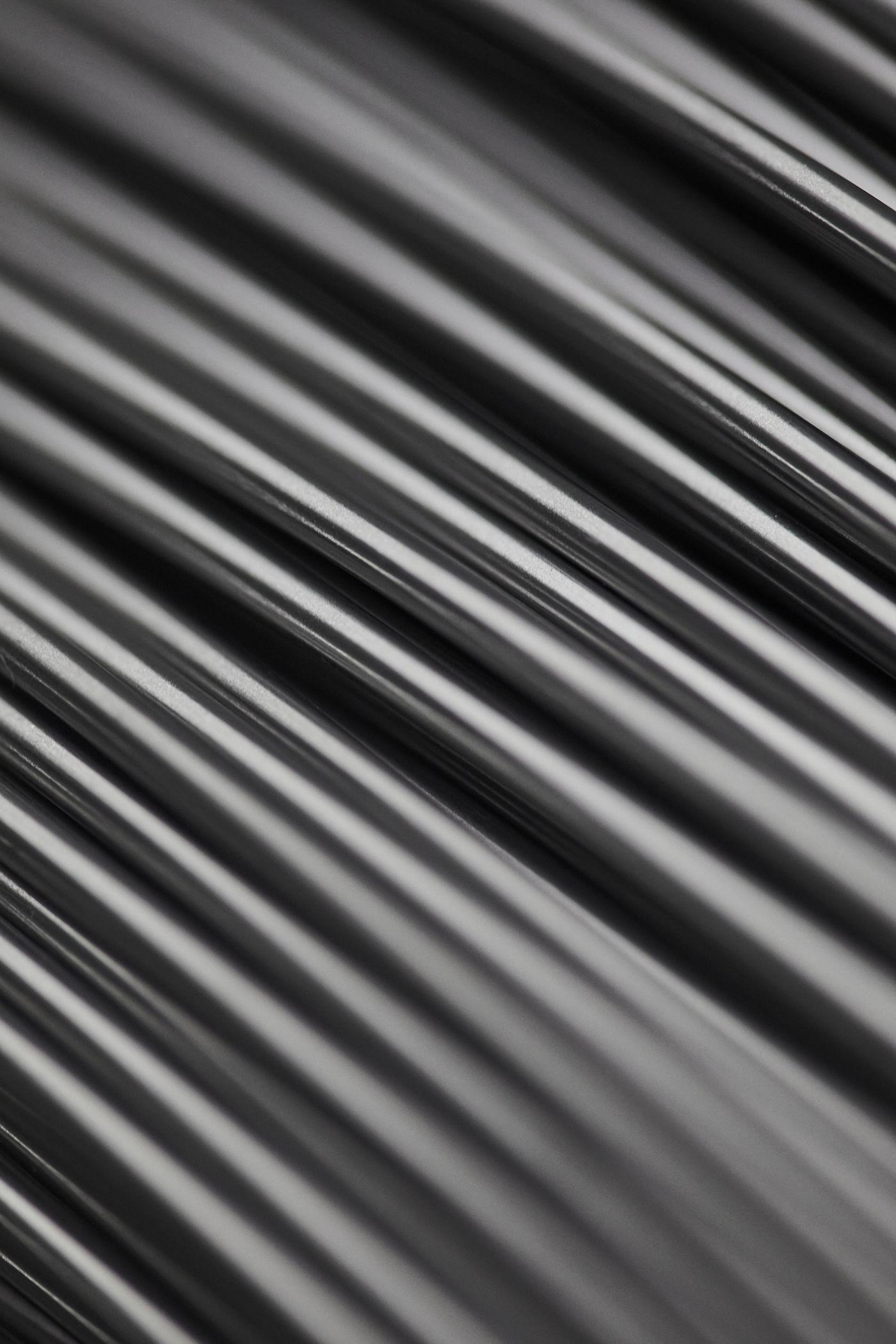

• SMA - Round Wire

Specification Range: φ0.10mm - φ6.0mm

We provide high tolerance for specifications; a single rod can weigh up to 30kg. The surface can either be oxidized black or polished bright. We provide wires in coil ad in fixed length.

- • SMA - Flat Wire

Thickness Range: 0.10mm - 2.0mm

Width Range: 1.0mm - 20.0mm

We provide different states of the wires, such as hard, semi-hard, soft and processing, Based on the phase transition principle, they are classified as low-temperature materials and room-temperature materials.

• SMA - Medical Field

The wires for medical application have specific phase transition temperature requirement. We offer grade AF05, AF15, AF25, they have great superelasticity when the environmental temperature is above 5℃、15℃ and 25℃. The AF series of SMA of our company are broadly used in the orthodontic, they have stable performance, consistent size, great processing plasticity and easy- to- polish surface.

Water pressure: 0.1Mpa~0.5Mpa, cold water temperature: 4 ℃~29 ℃, hot water temperature: 45 ℃~85 ℃Due to its high mechanical properties, corrosion resistance, and excellent biocompatibility, shape ...

moreWire diameter: ф 0.8mm~3.0mm, effective number of turns: ≥ 2Outer diameter: ф 6mm~30mm, free length ≤ 120mm, temperature control range 0ec~100-CThe memory alloy springs developed and produced by Q...

moreD (mm): 10-66, d (mmm): 5.3-3.7T (mm): 1-4.5, h (mm): 0.645-4.33, H (mm): 1.6-8.6In the power industry, loose power terminals can cause poor contact of conductors, leading to electrical sparking. The ...

moreThickness range: 0.1-2.0mm, width range: 1.0-20.0mmNarrow bands can be provided in hard, semi hard, soft, and processed states, and can be divided into low-temperature materials and room temperature m...

more